Any kind of machine or equipment will undergo a series of inspection and commissioning before leaving the factory until all links are qualified. Take the mobile elevator for example, the same is true. Of course, there will still be some questions about the elevator during the practice, but if there is no contact, you only need to grasp some specific information to effectively handle these questions.

4The daily maintenance of the cargo elevator should be carried out by a professional team (issued by the AQSIQ).

pAnaheimWhat role can the elevator play in installation? Before installation, confirm whether the motor and the elevator are intact,Hydraulic lifting platform and strictly check whether the size of each part connecting the motor and the elevator match. Here are the size and fit tolerance of the positioning boss,GasolFully automatic self-propelled elevatorDigital transformation boosts high-quality development input shaft and elevator groove of the motor.

What are the safety tools explosion-proof valves on mobile elevators? They are often seen in large hydraulic equipment, especially heavy equipment. The main effect is to avoid the problems of equipment caused by oil circuit cracking or excessive oil pressure. The installation of small elevator explosion-proof valves depends on the needs of customers, but large equipment basically needs to be installed.

MKonikiThe second is that steel will have obvious thermal expansion and contraction effect at low temperature. Although the nature of steel will be taken into account when designing and manufacturing hydraulic elevators, after all, the environment is different. At low temperature steel will have some unstable performance, such as increased hardness and decreased toughness. At this time, more attention should be paid to the maintenance of equipment to keep the key parts lubricated to avoid dry grinding.

SkThe lifting stage can realize the lifting of the double-deck table. It can also be assembled into ladder, multi-scape and multi-level stairs as required to form a group of lifting platforms, which can form different steps within the range of travel,Hydraulic lifting platform enrich the stage multifunctional effect. The telescopic stage is applicable to the equipment of the auditorium, theater, studio, cultural stadium, etc. The telescopic stage adopts an effective guidance system, which makes the gap between the telescopic platform and the fixed platform small, stable and stepless speed change during the translation process The synchronous device and electric device adopt the low-speed and large-torque drive device. During the telescopic process, they are parallel, free, telescopic in place,Hydraulic lifting platform and can automatically realize the application and characteristics of leveling stage elevator. The rotating stage has many functions, such as lifting,GasolFully automatic self-propelled elevatorDigital transformation boosts high-quality development rotating, tilting, and so on. Self-locking, interlock, travel switch mechanical limit, and is widely used in halls, theaters, multi-function halls,Lift_ Hydraulic elevator_ Hydraulic lift_ Hydraulic lifting platform - lift manufacturer studios, cultural stadiums, hotels and other cultural and entertainment places. Features: the hydraulic lifting stage is compact and stable in structure, and can adapt to high frequency continuous operation.

Pay attention to heat dissipation when the motor works in hot environment.

What are the safety tools explosion-proof valves on mobile elevators? They are often seen in large hydraulic equipment, especially heavy equipment. The main effect is to avoid the problems of equipment caused by oil circuit cracking or excessive oil pressure. The installation of small elevator explosion-proof valves depends on the needs of customers, but large equipment basically needs to be installed.

vCorrect maintenance of the hydraulic lifting platform and check the roller, intermediate shaft and bearing; Cylinder pin and bearing; Lubrication and wear of boom hinge shaft and bearing; Add lubricating oil to the above components. Extend the service life of the bearing.

IThe cleanliness of the hydraulic station is an important aspect of the lift hydraulic station, from a professional point of view, there are relevant rules and requirements. You should refer to the specification manual so that you can have a correct understanding and know how to achieve a better cleanliness.

PRecommendation and consultationManual hydraulic platform classification: manual hydraulic lifting platform car can be divided into manual hydraulic handling platform car, and manual hydraulic shear platform car.

mLMake the foundation according to the foundation plan, pay attention to the alignment, leveling and alignment, and ensure the level of the foundation and various use requirements.

Regularly add lubricating oil to maintain the lift: during the use of the lift, the friction between various components is also relatively large due to the heavy load, especially the lift chain and the lift pivot pin. It is necessary to ensure that the appropriate amount of lubricating oil is added before each use to ensure that the operation is flexible and not blocked. If the elevator is running, once“ appears; Squeak” It can be basically concluded that the friction noise is due to the lack of lubricating oil in the elevator. It is necessary to stop working immediately and find out the reason. It is easy to cause unpredictable hidden dangers. Point summary: it is not allowed to add lubricating oil regularly to maintain the elevator.

The oil cylinder seal is not replaced in the oil cylinder of the boarding bridge manufacturer. The lifting table does not lower. The lowering valve fails. When the lowering button is pressed check whether the lowering valve is powered on. If there is no electricity, try to eliminate it; If there is power, remove the fault of the lowering valve itself, or replace the lowering valve. The lowering valve should be kept clean and lubricated.

Respect for customerslHow to properly maintain the elevator and regularly replace the elevator hydraulic oil: The hydraulic oil used by the elevator is divided into winter and summer, which is something that many elevator customers do not pay attention to. They often inject hydraulic oil once and ignore it for a long time, and often do not realize it until it causes the elevator hydraulic oil cylinder to work abnormally.

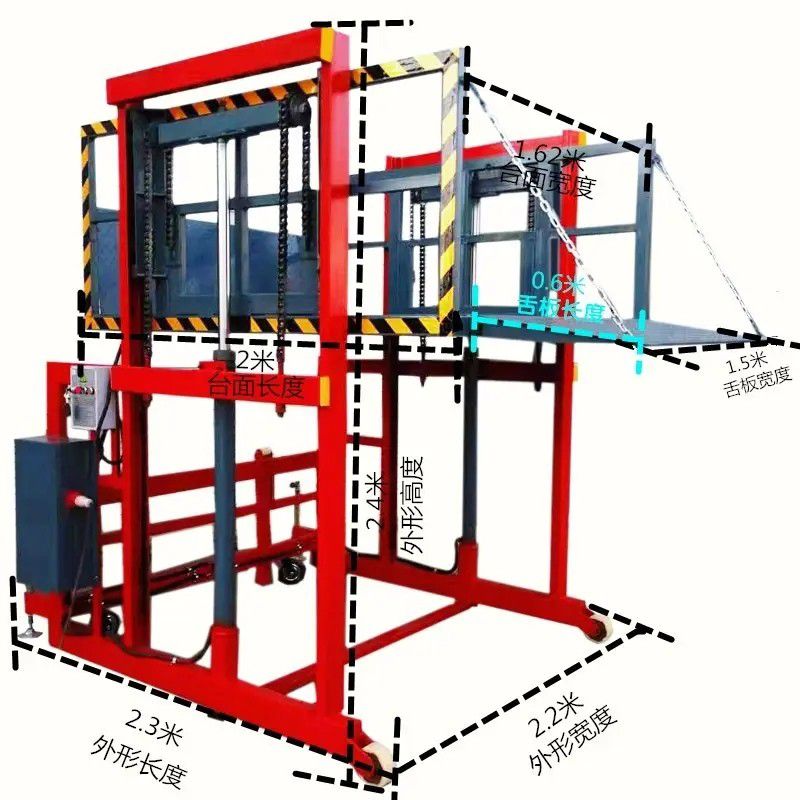

UWhat is the performance of guide rail type hydraulic cargo elevator: the equipment hydraulic system is equipped with anti-fall, upper and lower door interaction, and operation buttons can be set between floors and the equipment workbench to achieve multi-point. The product has solid structure, large load capacity, stable lifting, simple and convenient installation and maintenance. It is a good elevator alternative transportation equipment for goods transportation between low floors. According to the installation environment and use requirements of the hydraulic cargo elevator, different configurations can be selected and customized. The equipment is also widely applicable to explosion-proof enterprises such as chemical industry, power plant and pharmaceutical industry.

Novice operation: because novices do not know much about mobile elevators and other aerial work platforms, or do not understand the operation mode, it is easy to cause equipment failure due to operation errors. Operators in this field need to learn patiently and can only operate after training.

gAnaheimNovice operation: because novices do not know much about mobile elevators and other aerial work platforms, or do not understand the operation mode, it is easy to cause equipment failure due to operation errors. Operators in this field need to learn patiently and can only operate after training.

xFLoosening: The newly processed and assembled parts of mobile elevators and other aerial work platform equipment have a tendency to geometric shape and fit size. At the initial stage of use, due to the impact of alternating loads such as impact and vibration, or the impact of heating, as well as reasons such as excessive wear, it is easy to make the original fastening parts of mobile elevators and other aerial work platform equipment loose.

It is easy to cause the deterioration of lubricating oil in the process of wading. Especially in the steering, transmission and other systems the site should be disassembled and inspected. When the elevator is flooded, everyone should pay attention to it. The above points should not be ignored.

+8618006368428

+8618006368428 sellelevator@163.com

sellelevator@163.com