If the hydraulic valve is damaged, its effectiveness shall be maintained. If it is damaged it can be replaced in time.

3When using, the four legs should be firmly supported on the solid ground (subject to the fact that the walking wheel is about to leave the ground). Sleepers can be used when necessary.

qSazarunbutaAccording to the above three methods, it can effectively delay the aging of the hydraulic system of the hydraulic lifting platform. It is safe to use, comfortable to use and safe to use!

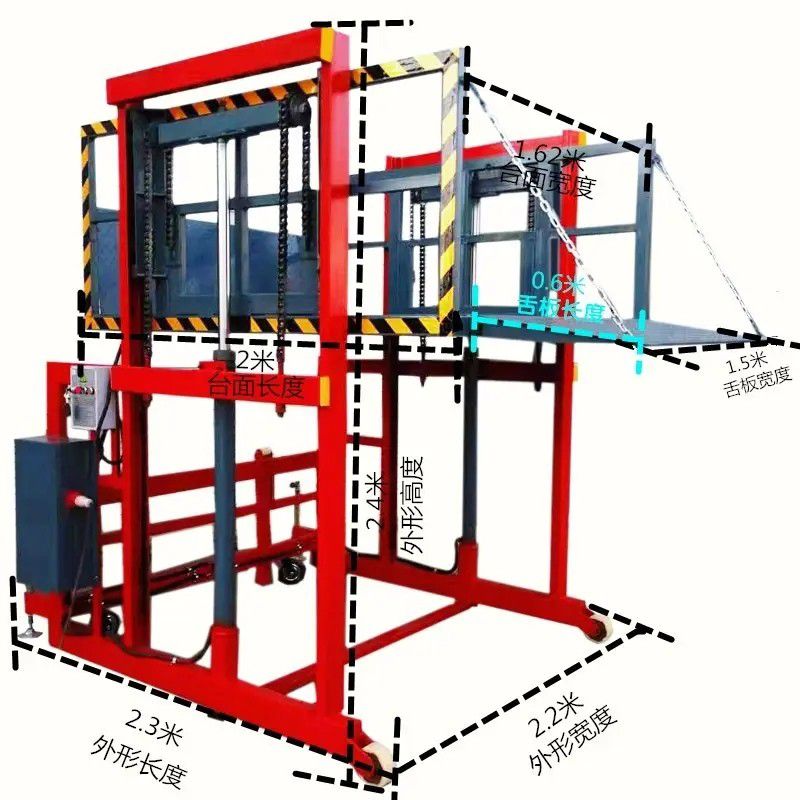

The concept of hydraulic boarding bridge The boarding bridge uses the power system. The large oil cylinder raises the entire equipment inclined plate. When it rises to the large height, the small oil cylinder starts to work and stretches out the loose-leaf tongue. All the equipment plates are effectively welded with high quality checkered steel plates and profiles,Hydraulic lifting platform efficiency and area of the electric lift,BelfortElevators used on construction sitesLow cost features most high-rise buildings will divide the electric lift into an array, each group is responsible for some floors, and make different adjustments and scheduling according to the use mode of different floors at different times.

So exactly how to replace the elevator hydraulic oil is the right way. In winter, the weather is cold, and the elevator hydraulic oil is easy to become thicker, so use thinner elevator hydraulic oil; In summer, the weather is relatively hot and the temperature is relatively high. The hydraulic oil of the elevator is easy to become thin, so it should be thicker. The interval for replacing the hydraulic oil of the elevator should be determined according to the local weather conditions. When replacing the hydraulic oil, use a filter screen to filter out the impurities in the hydraulic oil and store it for the next replacement in the next year. Summary: The hydraulic oil of the elevator should be replaced regularly when maintaining the elevator.

The check valve is damaged. The check valve is designed to prevent oil return. If there is a problem,Hydraulic lifting platform some oil will return, so it can be replaced at this time.

cThe single-column aluminum alloy elevator is easy to operate. The gantry cross-frame assembly is easy the operation is labor-saving, and the movement is flexible. It can cross obstacles such as fixed seats with a height of m, and can work stably on the steps. It is made of high-strength rectangular steel pipe with good rigidity and stability. Equipped with universal casters, flexible. The span of the frame at both ends is adjustable, which can be applied to the requirements of crossing different obstacles. The two ends of the rack are vertically adjustable and can be used for operation on a slope or step with a certain slope.

FThe production size of the support rod of the hydraulic lifting platform is inconsistent, which belongs to the quality defect of the lifting platform equipment itself. It is recommended to contact the manufacturer for replacement, which has a low probability.

VprojectIt is easy to cause the deterioration of lubricating oil in the process of wading. Especially in the steering, transmission and other systems, the site should be disassembled and inspected. When the elevator is flooded everyone should pay attention to it. The above points should not be ignored.

wZAt this time,Hydraulic lifting platform if the aerial work platform is overloaded, which can effectively avoid injuring the toes of the operator when the adjusting plate falls,BelfortElevators used on construction sitesLow cost features so as to ensure the safety of the equipment.

Now we have more and more demands for cargo elevators. Now lets introduce the maintenance of guide rail cargo elevators. When we normally use the rail-type cargo elevator, we should often carry out inspection, maintenance and maintenance, which can not only extend the service life of the rail-type cargo elevator, but also make it more powerful when it works! For example, the transmission part should have enough lubricating oil and the vulnerable parts must be regularly inspected, repaired or replaced. For the mechanical bolts, especiallyVibrating parts,Lift_ Hydraulic elevator_ Hydraulic lift_ Hydraulic lifting platform - lift manufacturer such as slewing bearing and lifting arm connecting bolts, should be checked for looseness. If they are loose, they must be tightened or replaced. Here are the eight steps of maintenance: the important maintenance work of the guide rail elevator. Regularly check the tire pressure of the guide rail elevator and whether the bearing condition is normal; Regularly check whether the structure of the support and panel is in good condition, and fill the bearing and sliding parts with lubricating oil and grease once a month; Vulnerable parts must be frequently inspected, repaired or replaced. Parts that are frequently vibrated, such as bolts and slewing rings, should be checked for looseness. If they are loose, they must be tightened or replaced.

For more, please checkjIs the water cooling and air cooling of the hydraulic station the same?

BHow to install and use the bearings of the elevator in the process of the bearing device of the elevator? We can not ensure that the bearing device is in the right position every time. It is inevitable that some devices are not in place or the bearings are offset. Once these problems occur in the device, the clearance between the bearings will become too small, and then the inner and outer rings of the bearings cannot be in the same rotation center. Therefore, when installing bearings, it is necessary to use special things, so as to ensure the success of the bearing device.

Before using the machine, the staff should carefully check the hydraulic and electrical systems, and use it only after there is no leakage or bare leakage.

kSazarunbutaDrain the hydraulic oil of the hydraulic elevator and discard it. For the outdoor guide rail elevator, tighten the connector and take out the oil filter. After cleaning, clean it with compressed air, and then put it back into the oil tank and connect the pipeline.

nUSome office buildings and hospitals may need several or even dozens of passenger lifts. In order to increase the speed, efficiency and area of the electric lift, most high-rise buildings will divide the electric lift into an array, each group is responsible for some floors, and make different adjustments and scheduling according to the use mode of different floors at different times.

The sinking of the cargo elevator is the phenomenon that the table top falls due to gravity after a certain period of time after rising to the specified position. Of course, this problem must be abnormal, so how to solve it? First of all, find out the reason. The following editor summarizes the ultimate solution.

+8618006368428

+8618006368428 sellelevator@163.com

sellelevator@163.com