What should we pay attention to when starting a new mobile elevator?

7The elevator is a common transmission equipment and the types selected in different fields are different. The guideway elevator is a kind that we all know. It is mainly used for the goods transmission between the floors of industrial buildings, restaurants and restaurants on the second and third floors. The low height is especially suitable for the workplaces where the pit cannot be excavated, double column, four column). So what should we do if the speed of the guideway elevator slows down in application?

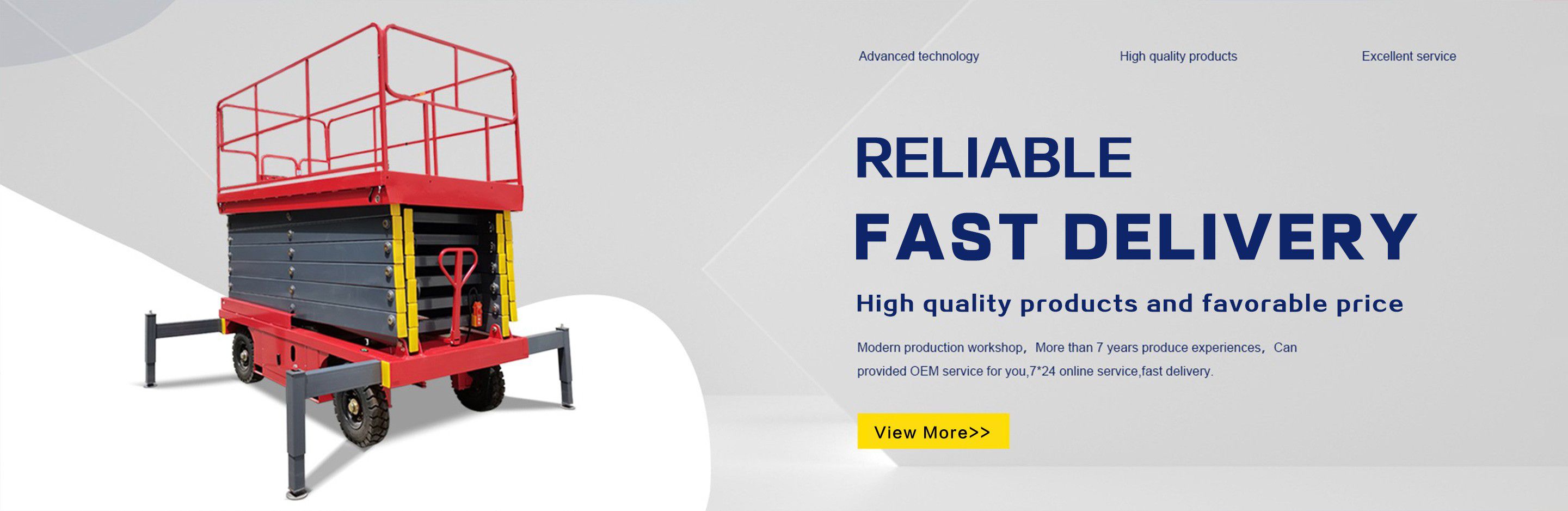

rWamzaThe hydraulic lifting platform mainly realizes the lifting function through the pressure transmission of hydraulic oil. Its shear fork mechanical structure makes the lifting of the elevator stable. The wide working platform and high bearing capacity make the high altitude operation range wide and suitable for multiple people to work at the same time. It makes aerial work efficient and secure.

The reason for the price of aluminum alloy lifting platform is that the hydraulic pump is also an important factor affecting the hydraulic oil flow. It is also easy to cause problems by using the hydraulic pump for a long time. When the platform speed of the hydraulic lift becomes slow, check whether the oil supply flow of the hydraulic pump remains unchanged. If the invention problem is real-time with the factoryContact the manufacturer to avoid the warranty period.

IBusiaThe reason for the price of aluminum alloy lifting platform is that the hydraulic pump is also an important factor affecting the hydraulic oil flow. It is also easy to cause problems by using the hydraulic pump for a long time. When the platform speed of the hydraulic lift becomes slow, check whether the oil supply flow of the hydraulic pump remains unchanged. If the invention problem is real-time with the factoryContact the manufacturer to avoid the warranty period.

RlImproper use of lubricating oil: poor lubrication and maintenance of aerial work platform equipment such as mobile elevator will also cause small fitting clearance of parts and components,Elevator manufacturer and the lubricating oil is not easy to form uniform oil film on the friction surface. In addition,Peter KuytroubnetskyLifts for construction sitesKnowledge of processing and maintenance due to assembly and other reasons, it is difficult to ensure the uniformity of fitting clearance, thus reducing the lubricating efficiency and causing early abnormal wear of equipment parts; In serious cases, the friction surface will be scratched or occluded, resulting in the occurrence of abnormal noise of the equipment.

Many times, when ordering large lifting platforms, after the customer has determined the parameters, the designer will first consider all aspects of the factors before design, including the size during transportation,Elevator manufacturer to prevent it from being difficult to transport to the customers installation site after being too wide, so during design and manufacturing, it is necessary to consider separate assembly or table split to meet the requirements. At the same time we should also consider the bearing capacity of the split, design and manufacture on the premise of ensuring the load and stability, and ensure that the equipment can be transported, hoisted and moved easily.

Double-column aluminum alloy lifting platform is beautiful and generous in design. It is made of high-strength aluminum alloy material, with large bearing capacity. The height is generally -m, and the load is kg-kg. Large table design allows one or two people to work at the same time.

yThe size of oil cylinder shall be reduced as much as possible under the condition that the design requirements are met. The smaller the cylinder size is, the faster the lifting speed is.

ZThe smooth and hydraulic oil of the slowing down box, gearbox,Elevator manufacturer external gear and other departments shall comply with the requirements in the smooth table.

MwhereCommon problems in the working process of hydraulic boarding bridge and specific solutions to motor phase loss (motor does not move and has buzzing sound)

fVThe anti-rust work of aerial work vehicles is generally something that needs attention when aerial work vehicles have not been used for a long time. How should we protect the body of aerial work vehicles from corrosion? In fact, it is very simple to go to the maintenance station for anti-corrosion,Peter KuytroubnetskyLifts for construction sitesKnowledge of processing and maintenance as long as our car owners can use some materials they can find, and pay attention to the driving habits to ensure that the aerial work vehicle does not rust. Here are some points for reference.

Hydraulic boarding axle“ Streamlined” The open loose-leaf joint design increases the welding area by more than times than the ordinary tubular joint, effectively prolongs the service life and simplifies the maintenance.

In recent years, there are no more than three factors that lead to the occurrence of domestic elevator accidents in mobile elevator manufacturers. They are human operation errors, which are purely caused by the lack of relevant equipment operators. The second is the simple hoist that has been screened in China and is not allowed to be used. This kind of hoist is potentially dangerous. And because the country has banned the production of this kind of simple hoist, the existing equipment is often aging, which is more prone to accidents. The third is that the quality of production is not up to standard, leading to severe social security incidents.

technological innovationwThe hydraulic torque converter and compensation system of mobile elevator are defective,Lift_ Hydraulic elevator_ Hydraulic lift_ Hydraulic lifting platform - lift manufacturer such as the hydraulic torque converter is weak, the power shift fails, the oil temperature is too high, the hydraulic torque converter is weak, the hydraulic oil quantity is insufficient, the pressure is not adjusted properly, the back pressure is insufficient, the torque converter oil quality is checked (whether the hydraulic transmission oil is misused), the amount is used, the torque converter pressure regulating valve, the back pressure valve and the set pressure value of the power shift fail, the quick-return valve, the power transmission valve The reversing valve is jammed and internally leaked. The oil pollution is serious. Check the cause of valve jamming and make corresponding elimination, filter or replace the hydraulic oil. If the oil temperature rises too high, check whether the cooler is defective. Check the hydraulic oil quality. The brand hydraulic boarding bridge is also known as the hydraulic loading and unloading platform. It can realize the rapid loading and unloading of the goods. It is simple in structure design flexible and convenient in use, high in efficiency, and is widely usedPopularize in the market.

IThe safety belt needs to be checked every six months. The load is kg and the test time is five minutes. After the test, check whether the safety belt is broken or deformed, and make a record of the test. The unqualified safety belt should be stopped immediately.

What are the safety tools explosion-proof valves on mobile elevators? They are often seen in large hydraulic equipment, especially heavy equipment. The main effect is to avoid the problems of equipment caused by oil circuit cracking or excessive oil pressure. The installation of small elevator explosion-proof valves depends on the needs of customers, and the corresponding anti-slip work shall be done; Remove the gear box of the equipment, remove the axle oil box, and take out the lower bearing and oil suction device; Slowly test run and check whether the surface around the axle diameter is seriously damaged; If the damage is serious and tungsten is occupied, polish it with oilstone; Under the motor, and with the sleeper on the trench edge inside the rail, use the jack to periodically pull the motor and remove the upper tile; How to solve the damage of the important equipment in the lifting platform? Check the status of the bearing pads and oil absorbers, investigate the cause of the damage, replace the bearing pads, and clean the bearing oil box; After assembling all parts and components, install a new oil suction device on the axle oil box and inject clean axle oil; The gear box shall be filled with gear lubricating oil as required; Burn of axle box bearing is the most common one, affecting the equipment operation.

oNThe reason for the price of aluminum alloy lifting platform is that the hydraulic pump is also an important factor affecting the hydraulic oil flow. It is also easy to cause problems by using the hydraulic pump for a long time. When the platform speed of the hydraulic lift becomes slow the axle box and wheel set will be fixed together, check whether the oil supply flow of the hydraulic pump remains unchanged. If the invention problem is real-time with the factoryContact the manufacturer to avoid the warranty period.

There are three movable plates on both sides of the adjusting plate, which can effectively avoid injuring the toes of the operator when the adjusting plate falls, so as to ensure the safety of the equipment.

+8618006368428

+8618006368428 sellelevator@163.com

sellelevator@163.com